Quality You Can Measure, Service You Can Count On

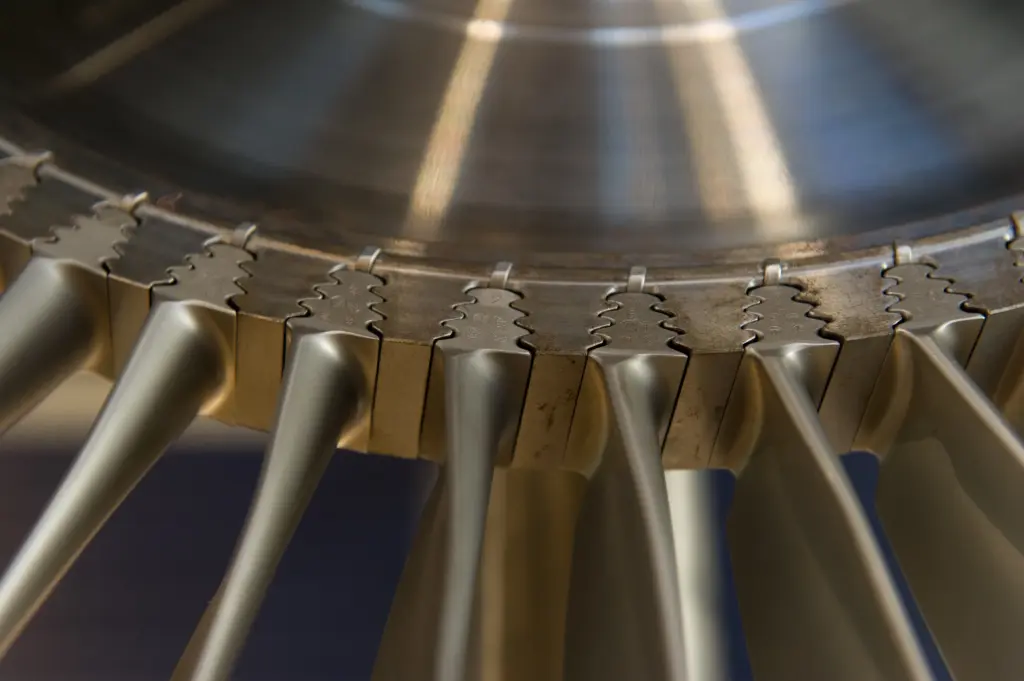

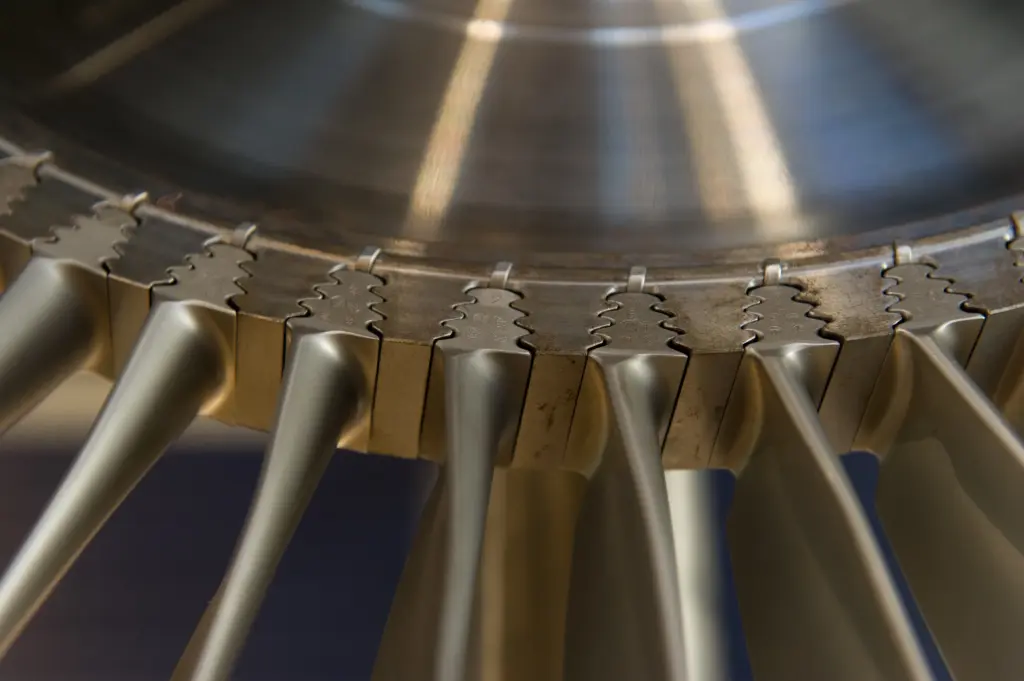

At South Coast Precision, we’ve built our reputation on delivering exactly what we promise – precision components to your specifications, on time. Our dedicated team takes personal ownership of every project, from single prototypes to production batches, with the attention to detail that comes from engineers who genuinely care.

With 20+ years of combined experience serving medical, aerospace, and defence sectors, we’ve invested in ISO 9001 certification and state-of-the-art inspection equipment because we know your components are critical. Your trust is earned with every delivery.

Equipped for Your Requirements

Our six-machine facility combines advanced CNC milling, turning, and laser marking capabilities to handle everything from intricate single components to complex batch productions - we've equipped ourselves to be your complete manufacturing solution.

{Another paragraph about Partners}

Materials

Steel • Stainless Steel • Engineering Plastics • Brass • Specialized Alloys

Production Range

One-off prototypes → Small batch runs → Volume production

Partners

lorum ipsum

Quality Inspection

lorum ipsum

A heading that should convince the visitor to buy

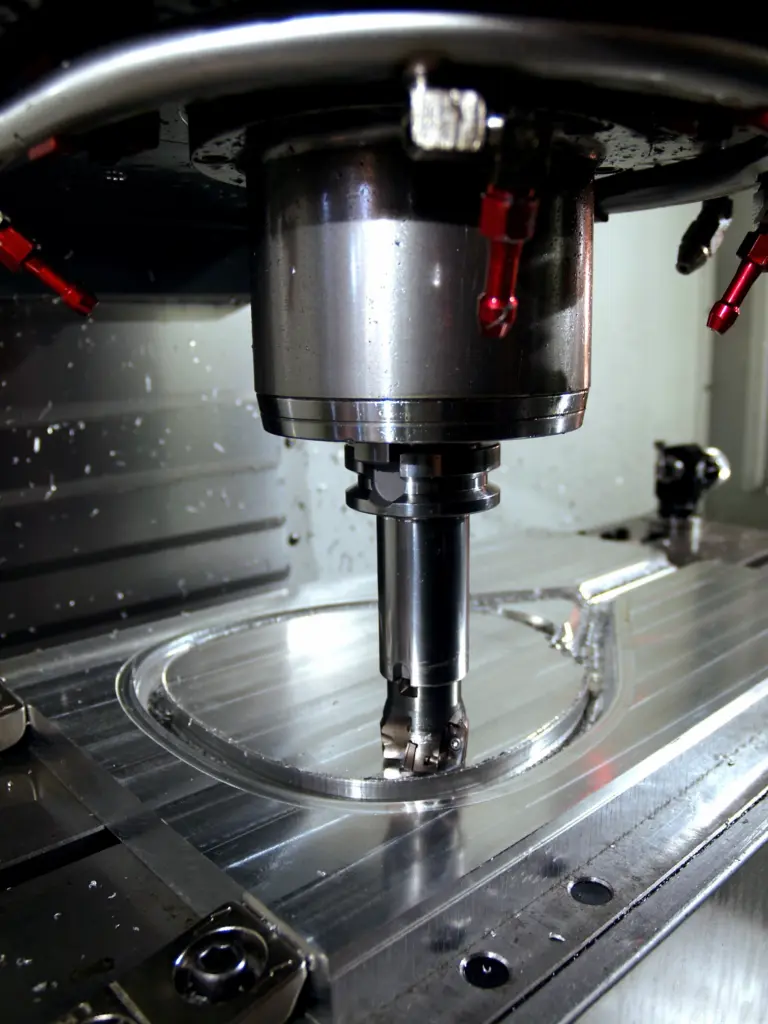

CNC MILLING

This is just placeholder text. Don’t be alarmed, this is just here to fill up space since your finalized copy isn’t ready yet. Once we have your content finalized, we’ll replace this placeholder text with your real content.

Bridgeport VMC600

X – 600mm

Y – 420mm

Z – 520mm

Bridgeport VMC600 with Hoffman Rotary axis

X – 600mm

Y – 420mm

Z – 520mm

Bridgeport VMC800 with Nikken Rotary axis

X – 800mm

Y – 510mm

Z – 560mm

A heading that should convince the visitor to buy

CNC TURNING

This is just placeholder text. Don’t be alarmed, this is just here to fill up space since your finalized copy isn’t ready yet. Once we have your content finalized, we’ll replace this placeholder text with your real content.

Colchester Tornado 210

Turning Ø – 350mm

Z – 320mm

Bar Capacity – 66mm

Doosan Lynx 220 with Tailstock and Bar Feed

Turning Ø – 320mm

Z – 305mm

Bar Capacity – 66mm

Doosan Lynx 2100 with Tailstock

Turning Ø – 350mm

Z – 330mm

Bar Capacity – 52mm

Denford Cyclone

Turning Ø – 158mm

Z – 210mm

Bar Capacity – 52mm

A heading that should convince the visitor to buy

Laser Part Marking

Compatible materials for our laser marking and engraving machines include stainless steel, aluminium, anodised aluminium, brass, copper, mild steel, tool steel, titanium, and more.

This is just placeholder text. Don’t be alarmed, this is just here to fill up space since your finalized copy isn’t ready yet. Once we have your content finalized, we’ll replace this placeholder text with your real content.

Boxford BFM110

110mm x 110mm work area

A heading that should convince the visitor to buy

Quality Inspection

Compatible materials for our laser marking and engraving machines include stainless steel, aluminium, anodised aluminium, brass, copper, mild steel, tool steel, titanium, and more.

This is just placeholder text. Don’t be alarmed, this is just here to fill up space since your finalized copy isn’t ready yet. Once we have your content finalized, we’ll replace this placeholder text with your real content.

Our Process

Streamlined From Start to Finish

It couldn't be simpler - here's how we operate to ensure your quality parts are delivered on time with no fuss.

Submit

Get the details of the job over to us along with your drawings.

Quote

We'll get a quote over to you within 3 working days, along with lead time.

Start

Your job is added to our ProShop ERP system on receipt of the your purchase order and confirmation is sent to your.

Inspect

First Article Inspection Report (FAIR), Coordinate Measuring Machine Report (CMM) and Certificates of conformity available upon request.

Deliver

After quality checks and inspections, your order is delivered to you, on time.

CAD Design

ProShop ERP

Why We Use ProShop ERP

We’ve chosen ProShop ERP as the backbone of our manufacturing operation, providing a comprehensive paperless management system that connects every aspect of our business. This industry-leading platform, built specifically for CNC engineering workshops, enables us to seamlessly manage everything from work instructions and drawing revisions to quality management and shop floor operations in a fully digital environment. Our team has instant access to schedules, job specifications, and real-time data, eliminating the inefficiencies of paper-based systems. ProShop’s centralised documentation ensures that every team member works from the same platform, with all blueprints, purchase orders, and process requirements stored in one accessible location.

How ProShop ERP Delivers Excellence to Our Customers

ProShop ERP enables us to deliver exceptional quality, reduced lead times, and complete traceability for every project. The system’s paperless operations and real-time monitoring capabilities help us maintain consistently low scrap rates, ensuring parts are manufactured correctly the first time and delivered on schedule. Automated quality assurance features allow us to proactively monitor production and maintain inspection intervals, identifying and addressing any deviations before they become issues. Every detail of your components is meticulously documented and easily retrievable, making repeat orders seamless whilst ensuring complete compliance with your specifications.

Whether you require aerospace-grade quality standards or specific industry requirements, ProShop’s comprehensive traceability and centralised documentation provide you with complete confidence in our commitment to delivering exceptional precision components on time, every time.We’ve chosen ProShop ERP as the backbone of our manufacturing operation, providing a comprehensive paperless management system that connects every aspect of our business. This industry-leading platform, built specifically for CNC engineering workshops, enables us to seamlessly manage everything from work instructions and drawing revisions to quality management and shop floor operations in a fully digital environment. Our team has instant access to schedules, job specifications, and real-time data, eliminating the inefficiencies of paper-based systems. ProShop’s centralised documentation ensures that every team member works from the same platform, with all blueprints, purchase orders, and process requirements stored in one accessible location.ProShop ERP enables us to deliver exceptional quality, reduced lead times, and complete traceability for every project. The system’s paperless operations and real-time monitoring capabilities help us maintain consistently low scrap rates, ensuring parts are manufactured correctly the first time and delivered on schedule. Automated quality assurance features allow us to proactively monitor production and maintain inspection intervals, identifying and addressing any deviations before they become issues. Every detail of your components is meticulously documented and easily retrievable, making repeat orders seamless whilst ensuring complete compliance with your specifications.

Why Choose South Coast Precision?

While other precision engineering firms promise quality and reliability, we prove it through consistent growth and lasting customer relationships. Since our founding seven years ago, manufacturers across critical industries have chosen South Coast Precision not just for one-off projects, but as their ongoing engineering partner. Here’s what sets us apart from the crowd:

This is just placeholder text. Don’t be alarmed, this is just here to fill up space since your finalized copy isn’t ready yet. Once we have your content finalized, we’ll replace this placeholder text with your real content.

This is just placeholder text. Don’t be alarmed, this is just here to fill up space since your finalized copy isn’t ready yet. Once we have your content finalized, we’ll replace this placeholder text with your real content.

This is just placeholder text. Don’t be alarmed, this is just here to fill up space since your finalized copy isn’t ready yet. Once we have your content finalized, we’ll replace this placeholder text with your real content.

Get in touch now

Your Quote

Just drop us a line or give us a call to get the ball rolling. Once we have the details we’ll get a quote to you in a few days.